Flow switch

Flow Switch – Working, Types, and Applications

A Flow Switch is a mechanical or electrical device that monitors the flow of air, liquid, or steam in a system. It helps detect whether flow is within the desired range and sends an electrical signal to control devices such as pumps, alarms, or safety interlocks.

Flow switches play a crucial role in preventing equipment damage caused by loss of flow, overheating, or dry running. They are commonly used in water treatment systems, chillers, fire protection, and HVAC systems.

⚙️ Working Principle

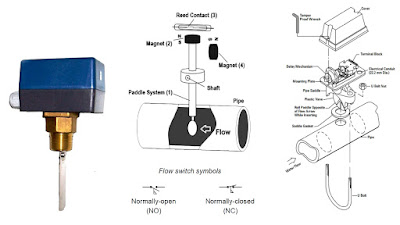

The flow of fluid pushes a paddle or sensor element inside the pipe. This movement changes the position of a mechanical lever or sensor element, activating or deactivating an electrical contact. The signal is then sent to a control system, pump, or alarm circuit.

Construction & typical components

Standard flow switches usually include:

- Body / housing (material matched to fluid)

- Sensing element (paddle, piston, thermal sensor, piezo sensor)

- Mechanical linkage and adjustment (set-point screw or cam)

- Electrical switching element (SPDT/SPST contacts, mercury or microswitch, or solid-state output)

- Connection method (inline threaded, insertion type, or external clamp)

🔍 Types of Flow Switches

- Paddle (Vane ) Flow Switch: Uses a paddle that moves with the fluid. Simple and widely used for water lines. a mechanical paddle protrudes into the flow; economical and reliable for liquids and air.

- Piston (Shuttle) Flow Switch: Measures flow using a spring-loaded piston; suitable for oils and viscous fluids. piston or shuttle movement actuates a contact; suited for oils, high-pressure lines and lubricating systems.

- Thermal Flow Switch: Works on heat transfer — used for gases and clean liquids. senses flow by temperature change of a heated element; often used for leak detection and liquid transfer monitoring.

- Piezoelectric Flow Switch: Uses vibration sensing for precise and compact systems like lubrication control. detects flow/no-flow by sensing vibrations or pressure pulses; useful for spray systems and food processing.

📊 Comparison Table

| Type | Sensing Method | Applications |

|---|---|---|

| Paddle Type | Mechanical displacement | Cooling water, pumps |

| Piston Type | Spring-loaded piston | Oil and lubrication circuits |

| Thermal Type | Temperature variation | Air flow, gas lines |

| Piezoelectric Type | Vibration sensing | Precise low-flow detection |

🧰 Installation Guidelines

- Install on a straight pipe section (10D upstream, 5D downstream).

- Ensure the flow direction matches the arrow on the body.

- Avoid mounting near bends, valves, or pumps to reduce turbulence.

- Use proper sealing to prevent leakage or false signals.

- Regularly inspect and clean the paddle or sensor for debris.

🔌 Wiring Diagram Example

🧠 Common Causes of Wrong Indication

- Air pockets in fluid line

- Improper mounting orientation

- Vibration or turbulence interference

- Debris buildup around the paddle

- Electrical contact failure

❓ Frequently Asked Questions (FAQ)

Q1: What is the difference between a flow switch and a flow meter?

A flow switch detects the presence or absence of flow, while a flow meter measures the exact flow rate.

Q2: Can a flow switch be used for gas?

Yes, thermal and piezoelectric flow switches are suitable for gas or air applications.

Q3: What maintenance is needed?

Clean the sensing element regularly, check electrical contacts, and verify calibration annually.

Q4: How do I test a flow switch?

Simulate flow or manually move the paddle to check continuity using a multimeter.

📘 Applications

Flow switches are used widely for:

- Pump protection — prevent dry running by ensuring minimum flow before pump energization.

- Cooling systems & heat exchangers — ensure adequate coolant flow.

- Fire control systems — verify water flow in sprinkler or deluge systems.

- Process safety — alarm or shut down when flow stops in hazardous ventilation or exhaust lines.

- Chemical dosing & water treatment — confirm dosing pumps are delivering flow.

- Oil well testing, drain line monitoring, relief valve monitoring and many other industrial uses.

Installation & best practices

- Install according to manufacturer orientation and recommended straight-run lengths upstream/downstream.

- Use the manufacturer-supplied fittings and follow torque/pipe prep instructions.

- Avoid locations with trapped air pockets; provide venting where needed.

- Verify set-point and hysteresis for the application; consider adjustable models for fine tuning.

- Periodically inspect paddle and pivot for wear, corrosion or fouling; recalibrate or replace as required.

📧 Email us at: nandantechnicals01@gmail.com

Comments

Post a Comment