PLC / SCADA / DCS – Interview Questions & Answers

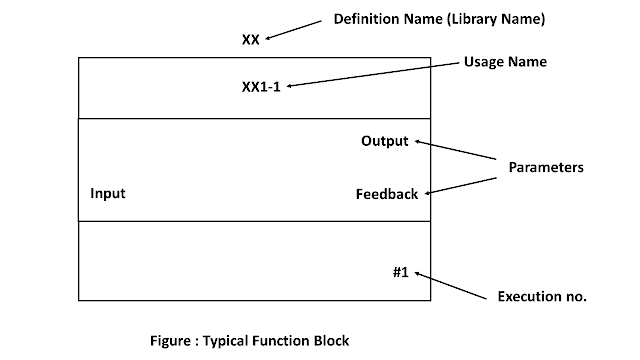

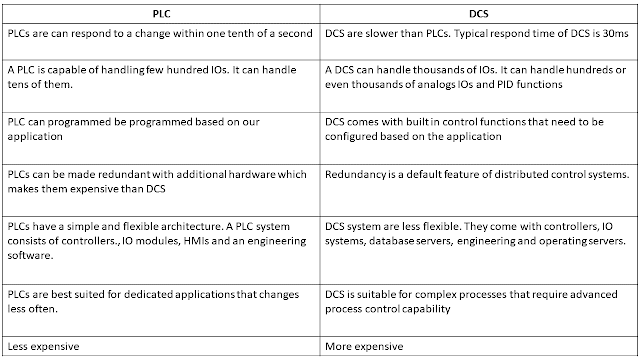

PLC / SCADA / DCS – Interview Questions & Answers 1. What is a PLC? A Programmable Logic Controller used to control machines, processes, and field devices. 2. Difference Between PLC, SCADA, and DCS Feature PLC SCADA DCS Purpose Control devices Monitoring & Control Process automation Architecture Centralized Central server + RTU/PLC Distributed Application Machines Plant monitoring Continuous process 3. PLC Scan Cycle Read Inputs Execute Logic Update Outputs Self Diagnostics 4. PLC Programming Languages (IEC-61131-3) Ladder Logic (LD) Function Block Diagram (FBD) Structured Text (ST) Instruction List (IL) Sequential Function Chart (SFC) 5. What is Ladder Logic? Graphical programming method using contacts and coils to represent relay logic. 6. NO & NC Contacts NO (Normally Open): Open in normal state. NC (Normally Closed): Closed in normal state....