Well type Manometer

Well type Manometer

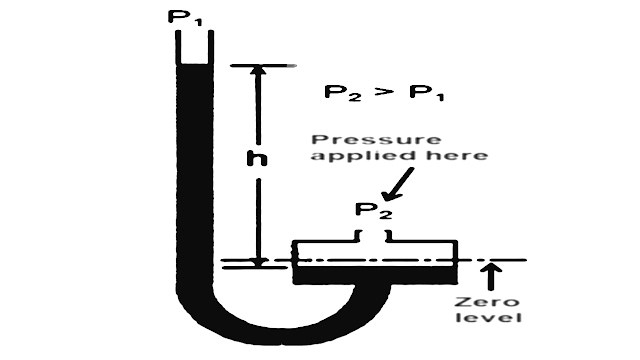

The well type monometer is widely used because of having only one leg. The main difference between a U-tube manometer and a well type manometer is that the U-tube is substituted by a large well such that the variation in the level in the well will be negligible and instead of measuring a differential height, a single height in the remaining column is measured.

It consist of a large diameter vessel with one side connected to very small size tube, so that the zero level moves very little when the pressure is applied. The area of well is much greater than the area of tube. In general this ratio is greater than 10. Accuracy is achieved by setting zero level of well at zero level of scale before each reading of table. The sensitivity of such monometer is good.

It consist of a large diameter vessel with one side connected to very small size tube, so that the zero level moves very little when the pressure is applied. The area of well is much greater than the area of tube. In general this ratio is greater than 10. Accuracy is achieved by setting zero level of well at zero level of scale before each reading of table. The sensitivity of such monometer is good.

Well Manometer Principle

Well Manometer same as the U-tube except for the reservoir on the high-pressure side. It is sometimes called a single column gauge.

The manometer consists of a metal well of large cross sectional area connected to a glass tube, or limb. This system normally contains mercury as the filling liquid.

The manometer consists of a metal well of large cross sectional area connected to a glass tube, or limb. This system normally contains mercury as the filling liquid.

As shown in figure above, both the well and the limb are open to atmosphere, in which case the level of mercury in the well is equal to that in the limb.

In the well type manometer, the pressure to be measured is normally applied to the well. When pressure applied to the well the level of liquid in the well falls by the distance ” x ” and the level in the limb rises by the distance ” h “.

When the column of liquid (h + x) exerts a pressure equal to the pressure applied to the well, the liquid stops moving.

The value of (h + x) will increase as the pressure to be measured increases and will decrease as the pressure to be measured decreases. The value of (h + x) can be read from a scale positioned as shown in the diagram above.

This scale is normally calibrated in units of pressure, e.g. mm of mercury gauge or Pascal ( Pa ), so that the pressure can be read directly from the device.

In a well-type manometer, one leg is replaced by a large diameter well. Since the cross-sectional area of the well is much larger than the other leg, when pressure is applied to the well, the manometer liquid in the well lowers only slightly compared to the liquid rise in the other leg.

As a result of this, the pressure difference can be indicated only by the height of the liquid column in the single leg.

For static balance,

In the well type manometer, the pressure to be measured is normally applied to the well. When pressure applied to the well the level of liquid in the well falls by the distance ” x ” and the level in the limb rises by the distance ” h “.

When the column of liquid (h + x) exerts a pressure equal to the pressure applied to the well, the liquid stops moving.

The value of (h + x) will increase as the pressure to be measured increases and will decrease as the pressure to be measured decreases. The value of (h + x) can be read from a scale positioned as shown in the diagram above.

This scale is normally calibrated in units of pressure, e.g. mm of mercury gauge or Pascal ( Pa ), so that the pressure can be read directly from the device.

In a well-type manometer, one leg is replaced by a large diameter well. Since the cross-sectional area of the well is much larger than the other leg, when pressure is applied to the well, the manometer liquid in the well lowers only slightly compared to the liquid rise in the other leg.

As a result of this, the pressure difference can be indicated only by the height of the liquid column in the single leg.

For static balance,

P₂ - P₁ = p (1 +A₁/A₂) h

where

A₁ = area of smaller-diameter leg

A₂ = area of well

If A₁/A₂ << 1, then P₂ - P₁ = ph

If the area of well is 500 or more times larger than the area of vertical leg, the error involved in neglecting the area term is negligible

Benefits

- Pressure or Vacuum Measurement

- Measures Differential or Point Pressure Readings

- Indoor or Outdoor Use

Applications

- Well type Manometer can be used in include anaerobic digester tanks/gas trains, boiler lines, engines, various plant utility lines and flares/waste gas burners.

- Easy panel mounting of the manometers provides a convenient single point for monitoring various pressures in the system.

Comments

Post a Comment