Difference between PLC and DCS

Difference between PLC and DCS

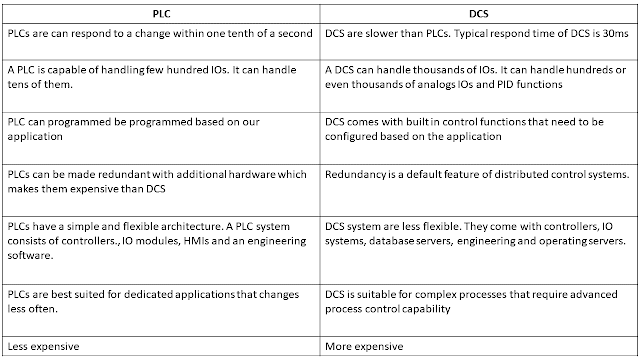

PLC

PLCs are can respond to a change within one tenth of a second

DCS

DCS are slower than PLCs. Typical respond time of DCS is 30ms

PLC

A PLC is capable of handling few hundred IOs. It can handle tens of them.

DCS

A DCS can handle thousands of IOs. It can handle hundreds or even thousands of analogs IOs and PID functions

PLC

PLC can programmed be programmed based on our application

DCS

DCS comes with built in control functions that need to be configured based on the application

PLC

PLCs can be made redundant with additional hardware which makes them expensive than DCS

DCS

Redundancy is a default feature of distributed control systems.

PLC

PLCs have a simple and flexible architecture. A PLC system consists of controllers., IO modules, HMIs and an engineering software.

DCS

DCS system are less flexible. They come with controllers, IO systems, database servers, engineering and operating servers.

PLC

PLCs are best suited for dedicated applications that changes less often.

DCS

DCS is suitable for complex processes that require advanced process control capability

PLC

Less expensive

DCS

More expensive

Comments

Post a Comment