Air and Fuel Ratio Control

Air and Fuel Ratio Control

In Combustion processes, air/fuel ratio is normally expressed on a mass basis. We get maximum useful heat energy if we provide air to the combustion zone at a mass flow rate (e.g. ib/min, kg/hr) that is properly matched to the mass flow rate of fuel to the burner.

Air and fuel ratio control Consider this generic equation for fuel combustion chemistry:

Fuel + Air =Useful heat + CO2 + H2O + CO + Unburned Fuel + Waste Heat Up the Stack

( CO + Unburned Fuel ) Increases as combustion air Decreases

( Waste Heat Up the Stack ) Increases as combustion air Increases

Where

CO2 = Carbon dioxide

CO = Carbon monoxide

H2O = Water

Air = 21% oxygen (O2) and 79% nitrogen (N2)

Fuel = Hydrocarbon such as natural gas or liquid fuel oil

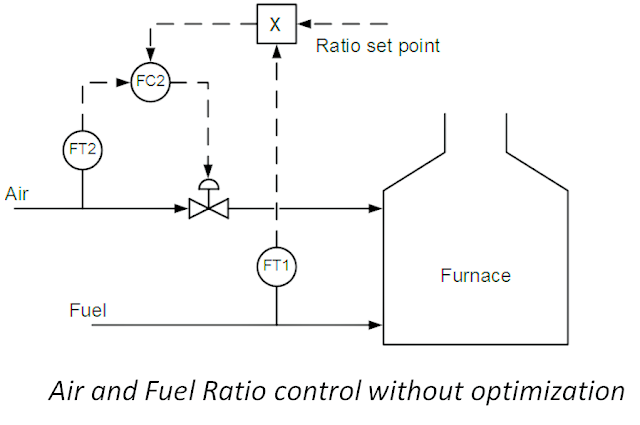

- Normally Air/Fuel ratio control is known as series control

- This means the change in air flow rate occurs as per ratio set only after the change has occurred in fuel flow rate.

- But in boilers used in power plants, fuel and air should be controlled in parallel rather than in series for safety reason

- This is necessary because a lag of only one or two seconds in measurement or transmission will seriously upset combustion condition in a series system

- This can result in alternating periods of excess and deficient combustion air

- Firing rate demand from the master control of the boiler is given as set point value to the fuel controller.

- Fuel flow rate changes as per the requirement of the master control.

- The same firing rate demand signal is simultaneously given to the air controller through a ratio setter so that the air flow rate is also controlled along with fuel flowrate maintain the proper ratio required for efficient combustion.

- Air is a largely composed of oxygen and nitrogen. It is the oxygen in the air that combines with the carbon in the fuel in a highly energetic reaction called Combustion. When burning hydrocarbons, nature strongly prefers the carbon-oxygen double bonds of carbon dioxide and will yield significant heat energy in an exothermic reaction to achieve to achive this CO2 form.

- Thus, carbon dioxide is the common green house gas produced from the complete combustion of hydrocarbon fuel. Water vapor (H2O) is also a normal product of hydrocarbon combustion.

- The final control element (FCE) for the combustion air stream, rather than being a valve, is more commonly a variable speed blower, perhaps with adjustable dampers or louvers.

- Measuring combustion air flow rate is challenging and can involve measuring a pressure drop across a portion of the combustion gas exhaust flow path.

- In different applications, the air flow rate can be the wild feed while fuel flow rate is the controlled feed.

- Stack gas analyzers add value and sophistication as they monitor the chemistry associated with combustion efficiency and environmental emissions.

- If the air/fuel ratio is too small in our heater, boiler or furnace, there will not be enough oxygen available to completely convert the hydrocarbon fuel to carbon dioxide and water.

- It leads to incomplete combustion of fuel. As the availability of oxygen decreases, noxious exhaust gases including carbon monoxide will form first.

- As the air/fuel ratio decreases further, partially burned and unburned fuel can appear in the exhaust stack, often revealing itself as smoke and soot.

- Incomplete combustion also means that, wasting expensive fuel. Fuel that does not burn to provide useful heat energy, including carbon monoxide that could yield energy as it converts to carbon dioxide, literally flows up our exhaust stack as lost profit.

- As the air/fuel ratio increases above that needed for complete combustion, the extra nitrogen and unneeded oxygen absorb heat energy, decreasing the temp. of the flame and gases in the combustion zone.

- As the operating temperature drops, one is less able to extract useful heat energy for intended application.

- If air/fuel ratio is too high, produce a surplus of hot air and carries its heat energy up and out the exhaust stack as lost profit.

Comments

Post a Comment