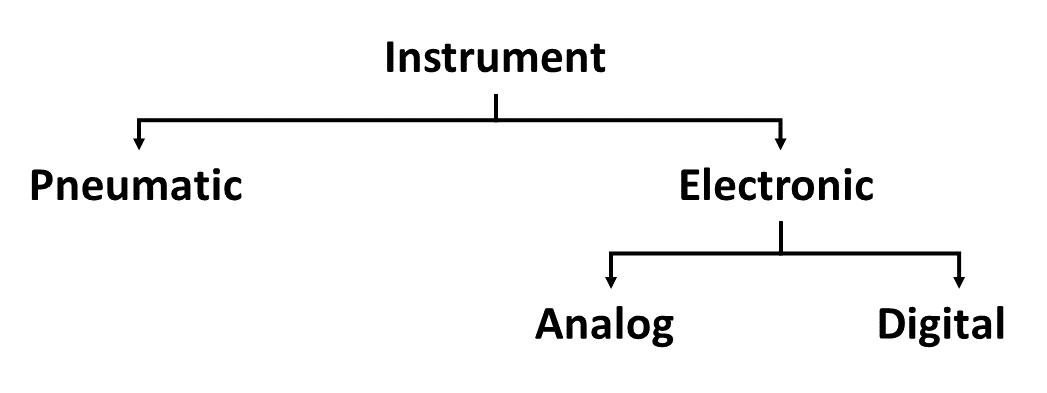

Instruments

Instruments Basically an instrument is a man made device which is used to measure a parameter of a physical variable. And it is variable analog as well as digital or a combination of digital and analog. Generally most industrial instrument is digital because digital instrument has more advantages compared to analog instrument . But in most cases the front end instrument is still analog and most signals from sensors or transducers are analog . Most sensors have the form of a chip and this smart sensor is directly connected or digital devices. The most basic and elementary components in all devices are sensors and transducers. Basically these outputs are current, voltage and power or amplitude, frequency or phase difference of energy. And all devices operate on signals. A signal is detected by a sensor from physical phenomena. The difference between analog and digital instruments is signal processing, and it requires different theoretical approaches and hardware. You may also like this: ...

.jpg)