Programmable Logic Controllers

Programmable Logic Controllers (PLC)

Overview, Architecture, and Applications

What is a Programmable Logic Controller (PLC)?

A Programmable Logic Controller (PLC) is an industrial digital computer used to control machinery and automation processes. It monitors input signals from field devices, processes them through programmed logic, and produces control outputs to actuators, relays, or motors.

PLCs are available in various sizes such as Nano, Micro, Medium, and Large PLCs. A Nano PLC may handle around 100 I/O modules, while a Large PLC can manage more than 5000 I/O modules.

Also PLCs are available in compact type and modular type and compact type PLC has fixed size I/O and all the modules included basically compact type PLC does not increase the number of I/O modules but modular PLC has modified these I/O modules as required. A PLC has a separate module and is placed in a rack or box type. Commonly PLC with SMPS and without SMPS. SMPS is a switch mode power supply and is also known as switching or switch mode power supply. Basically SMPS is used in PLC to convert AC supply to DC supply. And it converts 230 volt AC supply to 24 volt DC supply so PLC works on DC as well as AC supply. And the plc response time is a one tenth of a second. PLC takes digital signals or analog signals from field level components like sensors, actuators, valves and processes them and gives output or task to the system using PLC program. Basically PLC program controls the working of machine and system.

Types of PLC

- Compact PLC: Has fixed I/O and built-in modules. Expansion is not possible.

- Modular PLC: Offers flexibility to add more I/O modules as required.

PLCs operate using SMPS (Switch Mode Power Supply), which converts 230V AC to 24V DC. The PLC can therefore operate on both AC and DC supplies.

Technical Overview

The typical PLC scan time or response time is about one-tenth of a second. PLCs collect data from field devices, execute the user program, and control outputs in real-time to ensure efficient system automation.

History of PLC

The concept of PLCs originated in the 1960s with the development of the first Modicon PLC (now part of Schneider Electric), created to replace hard-wired relay control systems in the automotive industry.

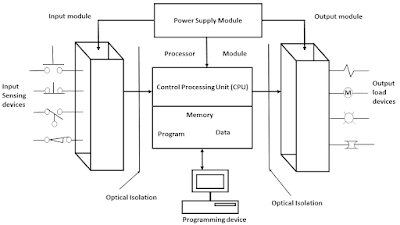

PLC Architecture and Components

- Power Supply: Converts AC mains to DC voltage for internal PLC operation.

- CPU (Central Processing Unit): Executes the control logic, processes data, and communicates with other modules.

- Input/Output Modules: Provide electrical isolation and connect PLC logic with field devices.

- Memory Unit: Stores user programs, process variables, and logic data.

- Programming Device: Used to write, modify, and upload control programs to the PLC.

PLC Programming Languages

- Relay Ladder Logic (RLL)

- Structured Text (ST)

- Function Block Diagram (FBD)

- Sequential Function Chart (SFC)

- Instruction List (IL)

Applications of PLC

- Industrial robot control

- Automated car parking systems

- Train control and signaling systems

- Food and beverage processing

- Material handling and conveyors

- Machine tools and packaging automation

- HVAC and building automation

What is PLC & How Does a PLC Work? | Complete Guide

What is a PLC?

A PLC (Programmable Logic Controller) is an industrial computer specially designed to control machines, processes, and equipment. It replaces traditional relay-based control panels and offers flexibility, reliability, and ease of troubleshooting.

PLCs are widely used in manufacturing plants, power stations, chemical industries, water treatment, and building automation.

How Does a PLC Work?

A PLC operates in a continuous scan cycle, which includes four main steps:

- Input Scan: The PLC reads the status of all input devices such as sensors, switches, transmitters, and push buttons.

Examples of field devices include:- PT (Pressure Transmitter)

- LT (Level Transmitter)

- MFM (Mass Flow Meter)

- XCV (Actuated ON-OFF Valve)

- VFD (Variable Frequency Drive)

- CV (Control Valve)

- Program Execution: The PLC executes the control logic written by the engineer using programming languages like Ladder Logic, Function Block Diagram (FBD), or Structured Text (ST). It performs arithmetic, comparison, and logical operations based on the inputs.

- Output Scan: After processing, the PLC updates the status of output devices such as motors, solenoid valves, alarms, and lights. Outputs can be digital (ON/OFF) or analog (4–20 mA, 0–10 V).

- Housekeeping / Communication: Finally, the PLC performs background tasks like self-diagnostics, communication with HMI/SCADA systems, and memory management.

This scan cycle repeats continuously — typically in milliseconds, ensuring real-time control.

PLC System Components

| Component | Function |

|---|---|

| CPU (Central Processing Unit) | Processes the program and makes decisions |

| Power Supply | Provides DC power to internal circuits |

| Input Module | Receives signals from field sensors and switches |

| Output Module | Sends control signals to actuators and field devices |

| Programming Device | Used to write and upload the control logic |

| Communication Ports | For networking with HMI, SCADA, and other PLCs |

PLC Control Example

Example: Motor Start/Stop Logic

- Inputs: Start Push Button, Stop Push Button

- Outputs: Motor Contactor Coil

When the Start button is pressed, the PLC energizes the motor output and latches it until the Stop button is pressed — all controlled via logic programming.

Advantages of PLC

- High reliability and processing speed

- Easy logic modification and troubleshooting

- Compact size and low maintenance

- Integration with SCADA / DCS systems

- Real-time monitoring and diagnostics

Summary

A PLC is the heart of industrial automation systems. It takes input from field instruments, executes a programmed logic, and sends output signals to control the process — making industries more efficient, safe, and intelligent.

Contact us: 📧 nandantechnicals01@gmail.com

Comments

Post a Comment