Coriolis Flow Meter

Coriolis Flow Meter

A Coriolis flow meter measures mass by the inertia of a liquid or gas flowing through a vibrating tube that is equipped with a set of sensors at the inlets and outlets of the meter. The increased movement of the flow produces measurable oscillation that is proportional to the mass. The design and function of Coriolis flow meters has made them the most reliable form of fluid and gas measuring instruments.

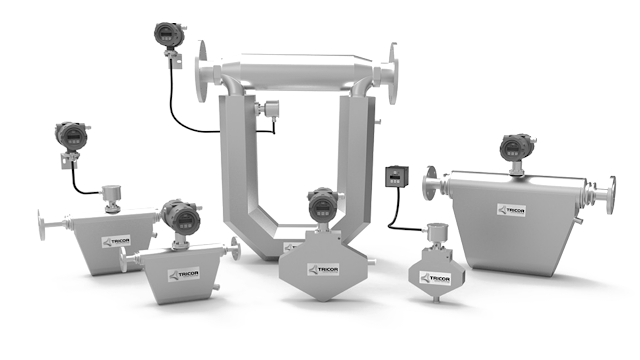

Types for Coriolis Flow Meters

- Single Tube Flow Meter

- Dual Tube Flow Meter

- Continuous Loop Flow Meter

- Straight Tube Flow Meter

- U Shaped Flow Meter

- Micro-Bend Flow Meter

- Triangle Shaped Flow Meter

Single Tube Flow Meter

The single tube design measures high fluid velocity that is created by reducing the cross sectional area in relation to the pipe. Tube distortion is measured in relation to a fixed point or plane. The tube is excited at a high amplitude bending force that is created at an anchored point.

Dual Tube Flow Meter

In the dual tube design of a Coriolis flow meter, a manifold splits the flow into each of the tubes. The vibrating tubes rotate around two fixed end points to create the Coriolis effect. When fluid is flowing through the U shaped tubes, the twist in the tubes accelerates on the inlet side and decelerates on the outlet side. The force between the inlet and outlet sides slightly twists the tubes in proportional to the mass flow rate. To enhance the Coriolis effect, a magnet and pickoff coil are attached at the inlet and outlets of the tubes. The coil moves into the magnetic field producing a sine wave proportional to the motion.

Continuous Loop Flow Meter

The continuous loop design is a form of single tube configuration where the flow is not divided but goes through a series of tubes. The Coriolis principle is the same in this type and supplies the same kind of data. In addition to the normal features, this design may have drivers and magnets connected. The continuous loop Coriolis flow meter is preferred for materials that can coat or clog the meter. To avoid clogging, they are sized with larger tubes.

Straight Tube Flow Meter

The straight tube design of a Coriolis flow meter can be either dual or single tubed. During fluid flow, the Coriolis forces act on the tubes and create distorted flexure that is detected by its sensors. A unique requirement of straight tube designs is strain gauges due to the rigidity of the tubes, which are used to detect dimensional changes in the tubes.

U Shaped Flow Meter

U shaped flow meters are the dual tube variety with two tubes shaped like a U with a magnetic and coil assembly. Sensors are placed at the inlet and outlets of the tubes. The Coriolis forces caused by the flow of the material determine the mass flow rate and density.

Micro-Bend Flow Meter

The micro-bend type of Coriolis flow meter has a U shape configuration, which has an extremely small radius. The smaller radii allow for a more compact design and a reduced pressure differential.

Triangle Shaped Flow Meter

The triangle shaped flow meter is very compact and designed for low pressure applications. The singular tube flow is smaller than U shaped models, which makes it more compact to save on installation space. Most triangle shaped flow meters produce multivariable measurements.

Benefits of Coriolis Flow Meters

- Accuracy: The main reason for the choice of a Coriolis flow meter over other types of meters for mass and density measurement is their accuracy, which is 0.1 of a percent. This one factor has been the reason for their rapid growth over the last decade.

- Adaptability: There are few limits to the types of substances a Coriolis flow meter can measure. Since they are not influenced by ambient conditions, they can be used to measure a wide assortment of gases, liquids, and fluids including high viscosity fluids, liquid-solid two-phase fluids, liquid-gas two-phase fluids containing trace gases, and dense high pressure gases.

- Flow Effect: When the flow of the material has a non-uniform or varying velocity from upstream and downstream pipelines, such disturbances and changes do not have an effect on the ability of the meter to take flow readings. This can be further improved by installing the meter on a straight line pipe as seen in the diagram below.

- Viscosity: One of the more difficult characteristics to measure in a fluid is viscosity, the thickness or texture of a material or the rate at which it deforms. This particular characteristic of fluids can be a challenge for standard meters but does not affect the readings of a Coriolis flow meter. Viscosity readings provide data on the thickness of a fluid as well as how easily it flows. The flow characteristic of different fluids can be seen in the image below where the fluid on the left flows easier than the fluid on the right.

- Data: A Coriolis flow meter is a multifunctional device that provides a set of readings regarding the movement and motion of a material through a pipeline. Though its primary function is to provide mass flow readings, it produces data regarding volume, density, temperature, and various other types of signals. The types of readings may vary across the different types of Coriolis flow meter producers but have basic similarities regarding measurements of mass, density, temperature, and viscosity.

- Bidirectional Flow Measurement: Bidirectional flow is not a very common factor in production operations but requires the same measurement as normal one directional flow. In bidirectional flow, the piping is used for flow in opposite directions. For most meters, a great deal of adjustment is necessary to measure flow in an opposite direction. This is not the case for a Coriolis flow meter due to its adaptability and ease of adjustment.

- Unique Fluid Measurement: Certain types of fluids are a mixture of fluids and gas. Measurement of such substances with these unique characteristics can be difficult due to their unusual nature. The ability of Coriolis flow meters to adapt to this type of unusual condition is another example of the meter‘s ability to perform regardless of the material being measured. Coriolis mass flow meters can be used to monitor the movement of asphalt, molasses, syrup, glucose, and slurry, which is another reason for the rapid growth of their use.

- Food Production: A basic requirement for food production is that all equipment must meet the exacting standards of the government Food and Drug Administration (FDA) that requires that devices used in food production be cleaned and sanitized regularly. Coriolis flow meters are used to measure the transfer of oils, cooking solutions, and water. They are the choice of the food industry because they can be easily cleaned multiple times to meet FDA standards.

Advantages of Coriolis Mass Flow meters

- Capable of measuring difficult handling fluids

- Independent of density changes, flow profile and flow turbulence. Hence straight lengths are not required.

- No routine maintenance required since no moving parts

- High accuracy

- True mass flow measurement

- Additional temperature and density measurements

- Very high accuracy for mass flow measurements

- Highly accurate density measurement

- Unaffected by pressure, temperature and viscosity

- No inlet and outlet sections required

- Operates in both flow directions (forward and reverse)

- Measuring range settings can be optimized for flow rate and density

- Self-draining

Disadvantages of Coriolis Mass Flow meters

- Not available for large pipes (upto 150 mm only)

- High flow velocities required for detection resulting in high pressure drop

- Expensive compared to other flowmeters

- Difficulty in measuring low pressure gases.

- Affected by gas inclusions

- Vibration sensitive when improperly installed

- Limited choice of materials

- Nominal diameter limited at the top

Applications

Coriolis flow meters are used in a wide range of critical, challenging applications, in industries including

- oil and gas

- water and wastewater

- power

- chemical

- food and beverage

- life sciences.

Some common applications for Coriolis flow meters include

- Applications with low to high flow rates

- Fiscal custody transfer

- Challenging liquid, gas and slurry applications

Questions and Answers

How does a Coriolis flow meter work?

Coriolis mass flow meters measure mass through inertia. A liquid or gas flows through a tube which is being vibrated by a small actuator. This artificially introduces a Coriolis acceleration into the flowing stream, which produces a measurable twisting force on the tube resulting in a phase shift.

What is a Coriolis Meter?

Coriolis mass flow meters work using the inertia caused by fluid or gas flowing through oscillating tubes. That inertia causes the tube to twist in proportion with the mass flow rate, and this twisting is measured with sensors to generate a linear flow signal. The first patents for meters based on this concept were granted in the 1950s, but it wasn’t until the 1970s that the first industrial versions of Coriolis mass flow meters were produced.

Where is Coriolis flow meter used?

Coriolis flow meters are used in a wide range of critical, challenging applications, in industries including oil and gas, water and wastewater, power, chemical, food and beverage, and life sciences.

Why we use Coriolis flow meter?

Coriolis mass flow meters provide extremely accurate measurements of both liquids and gases, regardless of heat, the speed of flow, and line pressure. This has helped to spur the use of more Coriolis gas flow meter systems in the petroleum industry.

Comments

Post a Comment