Coriolis flow meters working principle advantages, disadvantages and application

Coriolis flow meters

Coriolis flow meter operate on the principal that, if a particle inside a rotating body moves in a direction toward or away from the center of rotation, the particle generates inertial forces that act on the body.

The operation of a Coriolis flow meter is based on the mechanics of motion. The Coriolis force happens when a mass moves in a rotating inertial frame. The rotation is created by vibrating two opposing tubes on the flow meter. When a fluid flows through the opposed vibrating tubes, the tubes twist due to the Coriolis force. The twisting alternates with the vibration and creates two phase-shifted sinusoidal wave forms on coils mounted to the tubes. The amount of shift is proportional to the mass flow rate. In addition, the frequency of vibration is proportional to the fluid density.

Coriolis Flow Meter Principles

The basic operation of Coriolis flow meters is based on the principles of motion mechanics. As fluid moves through a vibrating tube it is forced to accelerate as it moves toward the point of peak-amplitude vibration. Conversely, decelerating fluid moves away from the point of peak amplitude as it exits the tube. The result is a twisting reaction of the flow tube during flowing conditions as it traverses each vibration cycle.

Importance

A Coriolis meter is based on the principles of motion mechanics. When the process fluid enters the sensor, it is split. During operation, a drive coil stimulates the tubes to oscillate in opposition at the natural resonant frequency. As the tubes oscillate, the voltage generated from each pickoff creates a sine wave. This indicates the motion of one tube relative to the other. The time delay between the two sine waves is called Delta-T, which is directly proportional to the mass flow rate.

Range

Coriolis flow meters are extremely important in a multitude of flow-measurement applications. Offering a wide breadth of line sizes, flow measurement accuracy and turndown, these meters support many industries and can measure flow rates from a few grams/hour up to 120,000 lbs/minute. Coriolis meters have a wide, dynamic range due to the linear nature of the signal created while measuring flow.

Coriolis Mass Flow Meter Working Principle

Mass flow meters are the types of flow meters which are mainly employed in mass-related processes such as chemical reactions, heat transfer, etc. In all these processes, accurate measurement of flow is the prerequisite.

There are numerous types of mass flow meters available in the industry. However, the most widely used type is the Coriolis meter. Another type available is thermal type mass flow meters

Coriolis Mass Flow Meter

A Coriolis meter works on Coriolis Effect, hence it is named so. Coriolis meters are considered to be true mass meters since they tend to measure the mass rate of flow directly while other flow meter technologies measure volumetric flow.

Since mass does not change, no adjustments are needed for varying fluid characteristics. Hence, a Coriolis meter operates in linear fashion.

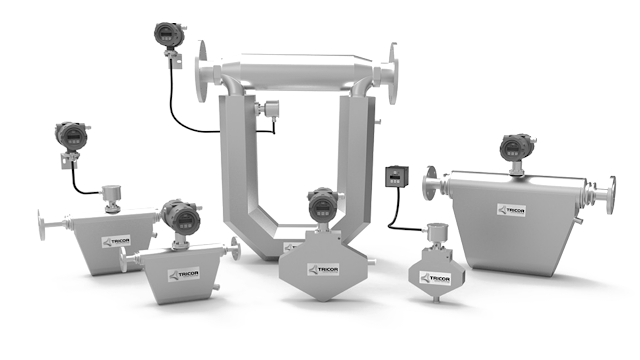

These types of meters exist in variety of designs.

The most common type of unit includes

- a U-shaped flow tube

- a sensor assembly

- an electronics unit

In this meter unit, the liquid passes through a U-shaped tube which vibrates in an angular harmonic oscillation. Coriolis forces will then deform the tube and a further vibration component gets added to the already oscillating tube. This added vibration element results in a phase shift or twist in few parts of the tubes.

This resulting phase shift which is directly proportional to the liquid mass flow rate is measured with the help of sensors. This measured information is further transferred to the electronics unit where it gets transformed to a voltage proportional to mass flow rate. A Coriolis meter is shown in the figure below:

Read more

Main Features

- A Coriolis meter can be applied for variety of applications ranging from adhesives and coatings to liquid nitrogen.

- Typical rangeability of curved tube designed Coriolis meters vary from 100:1 to 200:1 whereas for straight-tube meters its rangeability is limited i.e. about 30:1 to 50:1. Besides, accuracy of straight tube meters is low.

- In case of Coriolis meters, no compensation is needed for temperature and pressure variations. Also mass measurement is insensitive to changes in viscosity and density.

- They are particularly helpful for handling liquids whose viscosity changes according to velocity while temperature and pressure remains constant.

- These are called universal meters, since they are capable enough to measure nearly all liquids, slurries and gases. They can measure all liquid flows such as Newtonian, non-Newtonian and moderately dense gases as well.

- They can be employed to measure liquid density also.

- No Reynolds number restrictions are allied with Coriolis flow meters.

- They are also not affected by deformations in velocity profile.

- Advantages of Coriolis Meters

- Coriolis flow meter is capable of measuring a wide range of fluids that are often incompatible with other flow measurement devices. The operation of the flow meter is independent of Reynolds number; therefore, extremely vicious fluids can also be measured. A Coriolis flow meter can measure the flow rate of Newtonian fluids, all types’ non-Newtonian fluids, and slurries. Compressed gases and cryogenic liquids can also be measured by some designs.

- Coriolis flow meters provide a direct mass flow measurement without the addition of external measurement instruments. While the volumetric flow rate of the fluid will vary with changes in density, the mass flow rate of fluid is independent of density changes.

- Coriolis flow meters have outstanding accuracy. The base accuracy is commonly on the order of 0.2%. In addition, the flow meters are linear over their entire flow range.

- The rangeability of flow meters is usually on the order of 20:1 or greater. Coriolis flow meters have been successfully applied at flow rates 100 times lower than their full scale flow rate.

- A Coriolis flow meter is capable of measuring mass flow rate, volumetric flow rate, fluid density and temperature all from one instrument.

- The operation of the flow meter is independent flow characteristics such as turbulence and profile. Therefore, upstream and downstream straight run requirement and flow conditioning are not necessary. They can also be used in installations that have pulsating flow.

- Coriolis flow meters do not have internal obstructions witch can be damaged or plugged by slurries or other types of particulate matter in the flow stream. Entrained gas or slugs of gas in the liquid will not damage the flow meter. There are no moving parts witch will wear out require replacement. These design features reduces the need for routine maintenance.

- The flow meter can be configured to measure flow in either the forward or the reverse direction. In revere flow there will still be a time or phase difference between the flow detector, but the relative difference between the two detector signals will be reversed.

- Coriolis flow meter designs are available witch allow for use in sanitary applications, and for the measurement of shear sensitive fluids. Materials are available to permit the measurement of corrosive fluids.

Disadvantages of Coriolis Meters

- Coriolis flow meters are not available for large pipelines. The largest Coriolis flow meter that is currently available has a maximum flow rating of 25,000 lb/min (11,340 kg/min), and is equipped with 6 in. (15 cm) flanges. When larger flow rates must be measured, two or more flow meters mounted in parallel are required.

- Some flow meter designs require extremely high fluid velocities in order to achieve a significant amount of time or phase difference between the flow detector signals. This can result in extremely high pressure drops across the flow meter.

- Coriolis flow meters are expensive. However, the cost of a Coriolis meter is often comparable to (or below) the cost of a volumetric meter plus densitometer used together to determine the mass flow rate.

- Coriolis flow meters have difficulty measuring the flow rate of low- pressure gas. Application with pressure less than 150 psig are marginal with the flow meter designs that are currently available. Low-pressure gases have low density, and their mass flow rate is usually very low. In order to generate enough mass flow rates to provide sufficient Coriolis force to be measured, the gas velocity must be extremely high. This in turn may lead to prohibitively high pressure drops across the meter.

Applications

- Oil and Gas.

- Marine.

- Chemical and Petrochemical.

- Paints,Sealants, and Coatings.

- Food and Beverage.

Comments

Post a Comment