Types of Pumps

Types of Pumps

- Positive Displacement Pumps

- Dynamic Pumps

- Centrifugal pumps

- Submersible pumps

- Turbine pumps

- End-suction centrifugal pumps

- Jet pumps

- Floating pumps

Positive Displacement Pumps

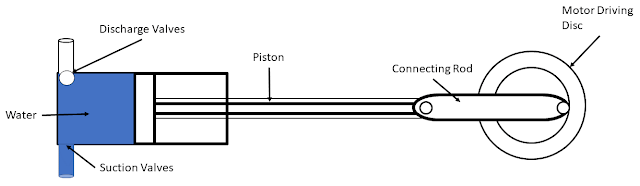

Positive displacement pump is also known as PD pump. positive displacement pump displaces or pushes the water from one place to another by mechanical energy. It has two sides – a suction side and a discharge side. The fluid goes into the suction valve and comes out through the outlet valve. They use the piston’s reciprocating, rotary, or linear motion to trap a fixed volume of fluid in a compartment inside the pump, which is then transferred or discharged outside through the nozzle. It operates by simultaneously filling the chamber with the fluid and then displacing it.

In positive displacement pumps, a piston or plunger inside a cylinder is the driving element as it moves in reciprocating motion.

The stroke length and, thus, the volume delivered per stroke is adjustable within a 10:1 range.

Rangeability can be increased to 100:1 by the addition of a variable-speed drive.

Example – Hand-pumps found in households, a common hand soap dispenser pump, etc.

Advantages of Positive Displacement Pumps

- They can deliver very high pressures (around 800 bar).

- They can handle fluids of high as well as low viscosity. The rate of flow increases with the increase in viscosity of the fluid.

- Their efficiency is high (more than 90 %).

- The rate of flow remains constant irrespective of changes in pressure.

- They are very durable and inexpensive.

- They can handle air or gas contamination in the liquid flow.

Disadvantages of Positive Displacement Pumps

- They require protection from over-pressure.

- They have a complex design when compared with centrifugal pumps.

- They require high maintenance, but it is not expensive.

Applications of Positive Displacement Pumps

- They can be used to irrigate the field.

- They can be used to pump spray paints, oils, and high force washing.

- They can be used for the transportation of oil or gas in the pipelines.

- They can be used in the manufacture of chemicals.

- They can be used to transport slurry of wastes in waste treatment plants.

Dynamic Pumps

Dynamic pump is a high-velocity pump. They increase the kinetic energy of the flow by mechanical motions, which then leads to the flow into the discharge pipe. Centrifugal pumps are a major sub-category of dynamic pumps.

These types of pumps can even work with saline water or sandy water. They’re usually fitted with filters to remove the solid contaminants in them. They can be used with all types of crops.

These include Centrifugal pumps

Centrifugal pumps

These pumps are the most commonly used type for irrigation practices. A centrifugal pump moves the fluid through the pump by virtue of rotatory motion. An impeller is the main device that rotates and draws the fluid inside the pump.

Centrifuge pump is always immersed in water, and its rotation transfers the kinetic energy to the fluid from the motor. Due to this kinetic energy, the fluid moves through the pump and departs through the discharge valve. They are usually operated by electrical energy. This electric energy can be from the regular public supply or from solar, wind, hydro energy, etc.

Some centrifugal pumps use centrifugal force to throw liquid radially outward while others, such as propellers, use a screw-type action that results in axial flow.

Between these two extremes, there is a whole continuum of impellers that change their pumping action from highly centrifugal radial to axial flow.

The line separating centrifugal and axial-flow pumps is vague, and the behavior of these pumps is usually described by the same laws

Advantages of Centrifugal Pumps

- They have a relatively simple design.

- There are no chances of leaks in the pumps.

- There is less loss due to friction.

- They are inexpensive.

- There is almost no noise.

- This pump has almost 100 % efficiency.

Disadvantages of Centrifugal Pumps

- The rate of flow is dependent on the pressure, and the pump works only at a certain pressure level.

- The rate of flow decreases when high viscosity fluids are used.

- It requires a constant flow of fluid; otherwise, a gas bubble may form, and it stops pumping.

- It requires priming.

- Ferrous particles in a liquid can cause corrosion of the impeller.

Applications of Centrifugal Pumps

- They are the most commonly used type of pumps in irrigation.

- They can pump harmful and risky liquids.

- They are used in mining, petrochemical industries, and domestic appliances.

- In the hydraulic control system.

- Used by firefighters and also to pump water into tanks on residential buildings.

The following pumps fall under the category of centrifugal pumps

- Submersible pumps

- Turbine pumps

- End-suction centrifugal pumps

- Jet pumps

- Floating pumps

Submersible pumps

Submersible pump is installed below the surface of the water. It consists of waterproof elements. They are used in a well, lake, or pond. They do not require priming. They are very efficient.

Submersible pumps can be single staged pumps or multi-staged pumps (a combination of many single staged pumps). They are usually operated by electrical energy. They can be operated by solar energy, wind energy, hydro energy, etc. They can be used when the water level of the water source is shallow.

Turbine pumps

Turbine pumps are also installed underwater. They have high efficiency, similar to submersible pumps. They can be used with wells, lakes, or ponds. The most common type of turbine pump is a vertical turbine pump.

Turbine pumps are usually operated by electrical energy. They can be operated by solar energy, wind energy, hydro energy, etc. They can be used when the water level of the water source is shallow.

End-suction centrifugal pumps

They are the most commonly used type of centrifugal pumps. All the portable types of pumps, including booster pumps, are end-suction centrifugal pumps. They are often connected with a rotating motor.

These pumps are not suitable to use when the water source is situated lower than 4 feet from the pump. They are usually operated by electrical energy. They can be operated by solar energy, wind energy, hydro energy, etc. They can be used when the water level is moderately deep.

Jet pumps

A jet pump or a hydraulic lift has the capability to lift water from a water source, which is situated very low from the level of the pump, but they have a lower flow rate. They are used to pump water from a river or a deeper water body.

They are usually operated by electrical energy. They can be operated by solar energy, wind energy, hydro energy, etc. They can be used to pump out water from a very deep water source.

Floating pumps

A floating pump is a normal centrifugal pump that is connected to a floating object. They are used to pump water from the surface of a lake or a pond. They generally make use of submersible pumps.

They are usually operated by electrical energy. They can be operated by solar energy, wind energy, hydro energy, etc. They can be used to pump water from a shallow water body.

Comments

Post a Comment