What are flange pipe fittings?

What are flange pipe fittings?

A flange pipe fitting is a fitting used to connect valves, pumps and other piping system equipment, basically these fittings are connected with the help of nuts and bolts. And flange joints are compressed by inserting donut-shaped gaskets before the bolts are tightened. A flange is an external or internal part used to connect pipes, valves and other equipment or to connect a piping system. Flange joints are mainly used on equipment joints like pipes, valves where frequent maintenance is required. A flange is a reinforcement or connection to another object, such as a flange at the end of a pipe, and flanges are used when joints need to be separated.

Flange

A flange is basically a metal ring that connects to a pipe or valve and other system. And usually this flange is attached to the end of the pipe and this flange has some holes to connect another flange using nut and bolt. The flange joints are pressure tightened by inserting donut-shaped gaskets before the bolts are tightened.

Basically the flange is made of metal and the metal is iron, aluminum, brass or steel. And access to the Common Benefit system is easy.

Flange is available in different types like threaded flange, socket weld flange, slip on flange, blind flange, weld neck flange, lap joint flange, reducing flange, elbow flange, weldo flange, expander flange, swivel ring flange.

Types of Flange

Welded neck flange

Welded neck flanges are used for high temperature, high pressure operation or wide fluctuations in pressure and temperature. Basically this flange is useful for handling expensive, hazardous, flammable, explosive fluids, as failure or leakage of flange joint can be fatal to the plant. Various dimensions specified for welded neck flanges such as outside diameter and outside thickness of flange, outside diameter of raised face, diameter of hub at base, diameter of hub at welding point, length from hub, diameter of hole and number of holes, diameter of bolt and diameter of bolt circle.

Advantage of welded neck flange

- Welded neck flange connection is not easy to deform.

- This flange is suitable for pipes with large fluctuations in temperature or pressure, or for pipes with high temperature, high pressure and low temperature.

- This flange is also used for pipes conveying expensive medium, flammable and explosive medium and toxic gases.

Disadvantages of welded neck flange

- Flange bulky with neck butt welding

- Welded neck flange is more expensive

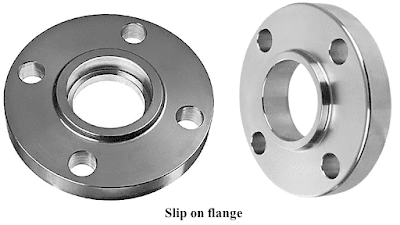

Slip on flange

Due to the ease of alignment in welding, this flange is widely used and the cost of this flange is also low. The flange is suitable for moderate service processes where temperature, pressure changes, vibration, shocks are not severe. Its strength is about 70% that of welded neck flange and its fatigue life is about 1/3 that of welded neck flange.

Screwed flanges

Screwed flanges can be connected to threaded pipes without welding. And it is generally not useful for operations involving bending or thermal cycling, as there is always the possibility of leakage from threaded joints. It can be satisfactorily used for high pressure operations with high alloy steel as welding of high alloy steel is difficult.

Lap joint flange

A lap joint flange is usually used with a lap-joint and a hub. This flange is useful or used where temperature changes, pressure changes, vibrations and shocks are not severe. These flanges are not useful where there is severe bending stress. This flange has only 10% fatigue compared to the welded neck flange. The bolt holes for this flange can be easily aligned and this facilitates the installation of larger diameter vessels. These flanges are useful for operations where the vessel is frequently opened for cleaning and inspection.

Blind flanges

Blind flanges are commonly used for pressure vessel openings e.g. Hand holes and inspection parts. These are also used on the ends of pipes and valves. These flanges are capable of handling high bending stresses but do not require stress absorption due to thermal expansion. These flanges are used for heat exchangers. A blind flange is a flat plate. It is only supported on the gasket load reaction line. It is loaded by gasket seating load and a combination of gasket seating load and uniform pressure load.

Threaded flange

Threaded flanges are used for special situations and their main advantage is that they can be attached to the pipe without welding. Sometimes a seal weld is also used in conjunction with a threaded connection. This special type of flange is typically used for high pressure piping systems, albeit for smaller diameter applications. Obviously, the larger the flange, the more difficult the ability to machine the thread.

Spectacle flange

A spectacle blind - also called a figure-8 blind - is usually a piece of metal cut to fit between two pipe flanges and usually sandwiched between two gaskets. A spectacle blind is often made from two metal discs that are connected to each other by a small piece of steel. The shape resembles a pair of spectacles or "spectacles" - hence the name spectacle blind. One end of the blind shall have an opening to allow flow through the pipe during operation and the other end shall be solid to prevent flow during maintenance. They are usually installed as permanent equipment to separate process piping systems.

Integral Flange (Long Weld Neck Flange)

Integral flanges also called long weld neck flanges (LWN flanges) are used for high pressure conditions, integral hub weld neck flanges are used and long welding neck flanges are preferred for very high pressure cases. In this case, the welds are away from the ring to prevent bending stress and weld stress from combining.

Orifice flange

Orifice flanges are used with orifice meters for the purpose of measuring the flow rate of liquids or gases in the respective pipelines. Orifice flanges usually come with top faces or RTJ (Ring Type Joint) facings. They are, for all intensive purposes, similar to weld necks and slip-on flanges with additional machining. They have a variation of radial tapped holes in the flange ring. For fitting of meter connections and orifice plate carriers. Additional bolts act as jacks to separate the two flanges to replace the orifice plate or for other inspection services.

Socket weld flange

A socket weld flange is similar to a slip-on flange, however, socket welds have an internal recess on the inside diameter to facilitate flow of the process fluid. A positive advantage of this is that with proper welding and grinding a smooth bore is produced. The downside of this type of flange is that it can be more expensive than a slip-on due to more complicated machining, and they may be less readily available than a slip-on because the bottom half of the inside diameter must be the same. A schedule is made similar to the pipe used. (You must specify the required schedule) These socket weld flanges were initially developed for use on smaller pipe sizes at higher pressure ratings.

Plate flange

A plate flange is a flat, circular disc that is welded to the end of a steel pipe and bolted to another pipe. Typically used in fuel and water pipelines, two flange plates will be joined together with a gasket between them. The flange plate will have bolt holes around the perimeter and will be used to form junctions, tees and joints.

Comments

Post a Comment