Building Automation System

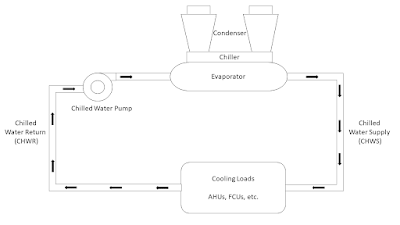

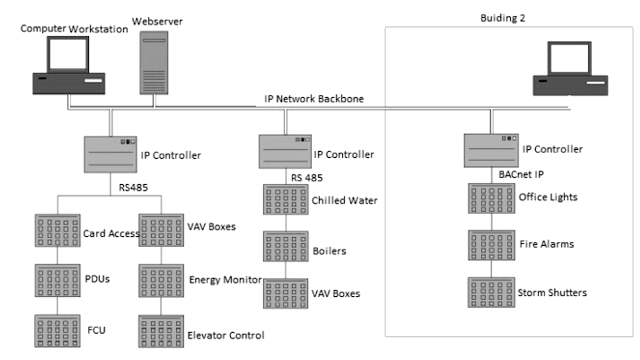

Building Automation System A Building Automation System (BAS), (also referred to as a Building Management System or a Building Control System), is a system that controls various electric, electronic and mechanical systems throughout a building. It is a distributed control system that integrates different types of building systems together into one centralized location. Building automation systems are primarily utilized to control the heating, ventilation, and air conditioning (HVAC) in a building, but are also used to control lighting, security and other building systems. BAS works as a computer networking system that monitors and controls a range of other electronic and mechanical systems. It provides a means for these disparate systems to communicate across platforms, software and languages. Building Automation System benefits An extensive BAS can control many systems (such as fire and flood safety, ventilation and security) at one time, which diminishes the opportunity for huma...