Integrated Building Management System

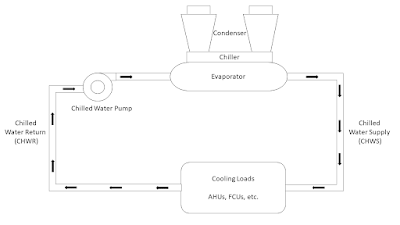

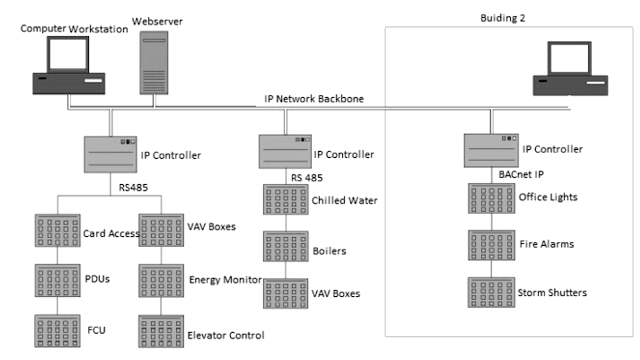

Integrated Building Management System IBMS stands for Integrated Building Management System. An Integrated Building Management System is a single, comprehensive building management system for HVAC, lighting, security, fire and other systems. The Building Management System (BMS) can be defined as the system installed in buildings that controls and monitors the building’s mechanical and electrical equipment, such as heating, cooling, ventilation, and lighting. These systems typically represent 70% of a building's energy usage. Obviously, the role of BMS is crucial in management of the building’s energy demand. Beyond controlling the internal environment of the building, the IBMS (Integrated Building Management System) covers also access control, intruder alarms, video surveillance, monitoring of fire alarm system and other systems as applicable. IBMS can be referred to as the Integrated BMS and Security System the single, uniform system for building management. Application of full IB