Hall Effect Sensor

Hall Effect Sensor

Hall Effect Sensor Definition

Hall-effect sensors are the linear transducers that are used to measure the magnitude of the magnetic field. Working on the principle of Hall Effect, these sensors generate a Hall voltage when a magnetic field is detected, which is used to measure the magnetic flux density.

Linear sensors can measure the wide range of magnetic fields. Besides magnetic fields, these sensors are also used for detecting proximity, position, speed. For these sensors output voltage is directly proportional to the magnitude of the magnetic field.

Introduction

The basic Hall Element of the Hall Effect magnetic sensors mostly provides very small voltage of only a few micro volts per Gauss, so therefore, these devices are usually manufactured with built-in high gain amplifiers.

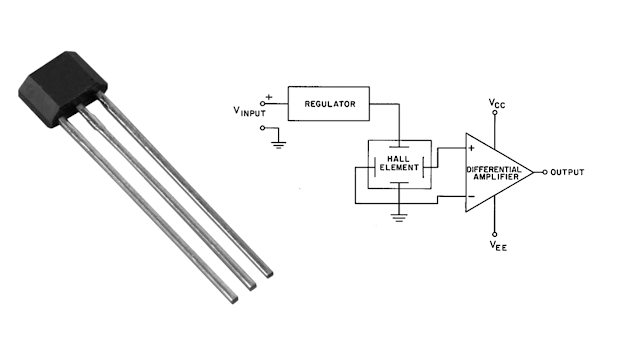

There are two types of Hall Effect sensors, one providing analog and the other digital output. The analog sensor is composed of a voltage regulator, a Hall Element and an amplifier. From the circuit schematics we can see that the output of the sensor is analog and proportional to the Hall Element output or the magnetic field strength. These type of sensors are suitable and used for measuring proximity because of their continuous linear output.

On the other hand, the digital output sensors provide just two output states, either “ON” or “OFF”. These type of sensors have an additional element, as illustrated in the circuit schematics. That’s the Schmitt Trigger which provides hysteresis or two different thresholds levels so the output is either high or low.

An example of this type of sensor is the Hall Effect switch. They are often used as limit switches, for example in 3D printers and CNC Machines, as well as for detection and positioning in industrial automation systems.

Other contemporary applications of the Hall Effect sensors are measuring wheel/ rotor speed or RPM as well as determining position of crankshaft or camshaft in engine systems. These sensors are composed of a Hall Element and a permanent magnet which are placed near a toothed disk attached on the rotating shaft.

The gap between the sensor and the teeth of the disk is very small so each time a tooth pass near the sensor it changes the surrounding magnetic field which will cause the output of the sensor to go either high or low. So the output of the sensor is a square wave signal which can be easily used for calculating the RPM of the rotating shaft.

Working Principle of Hall Effect Sensor

The principle of Hall voltage is used as a working principle of the Hall Effect sensor. On a thin strip of a conductor, electrons flow in a straight line when electricity is applied. When this charged conductor comes in contact with the magnetic field which is in a perpendicular direction to the motion of electrons, the electrons get deflected.

Some electrons get collected on one side while some on another side. Due to this, one of the conductor’s plane behaves as negatively charged while the other behaves as positively charged. This creates potential difference and voltage is generated. This voltage is called the Hall voltage.

The electrons continue to move from one side of the plane to other till a balance is achieved between the force applied on charged particles due to an electric field and the force that caused magnetic flux that caused this change. When this separation stops, the hall voltage value at that instant gives the measure of magnetic flux density.

Based on the relation between hall voltage and magnetic flux density, Hall Effect sensors are of two types. In the linear sensor, the output voltage is linearly related to magnetic flux density. In the threshold sensor, at each magnetic flux density, the output voltage will have a sharp decrease.

Hall Effect sensors can be viewed as linear transducers. To process the sensor’s output these require a linear circuit that can provide a constant driving current to the sensors and also amplifies the output signal.

Applications of Hall Effect Sensor

- When combined with threshold detection they act as a switch.

- These are used in ultra-high-reliability applications such as keyboards.

- Hall Effect sensors are used to time the speed of wheels and shafts.

- These are used to detect the position of permanent magnet in brushless electric DC motors.

- Hall Effect sensors are embedded in digital electronic devices along with linear transducers.

- Sensing the presence of the magnetic field in industrial applications.

- Used in smartphone to check whether the flip cover accessory is closed.

- For contactless measurement of DC current in current transformers, Hall Effect sensor is used.

- This is used as a sensor to detect the fuel levels in automobiles.

Comments

Post a Comment