Proximity Sensor

Proximity Sensor

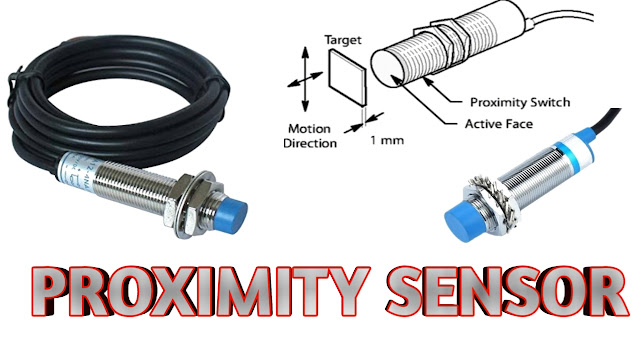

A proximity sensor detects an objects when the object approaches within the detection range and boundary of the sensor.

Proximity sensors include all sensor that perform non contact detection in comparison to sensors such as limit switch, that detects the object by physically contacting them.

Proximity sensors are used in various facets of manufacturing for detecting the approach of metal and non metal objects.

What are proximity sensors?

A proximity sensor is a sensor able to detect the presence of nearby objects without any physical contact. Most likely a plate of glass or plastic separates the two. Although you are likely to touch the separating element, there is no physical contact with the sensor. Proximity sensing technology enables adaptive controls, alleviates isolation issues, improves overall application robustness, generates almost unlimited design flexibility and fosters new functionalities.

Types of Proximity Sensor

- Inductive proximity sensor

- Capacitive proximity sensor

- Ultrasonic proximity sensor

- Optical proximity sensor

Inductive proximity sensors

An inductive sensor is an electronic proximity sensor, which detects metallic objects without touching them.

Electric current generates a magnetic field, which collapses generating a current that falls asymptotically toward zero from its initial level when the input electricity ceases.

Construction and working

The Main Components Of The Capacitive Proximity Sensor Are Plate, Oscillator, Threshold Detector And The Output Circuit.

The Plate Inside The Sensor Acts As One Plate Of The Capacitor And The Target Acts As Another Plate And The Air Acts As The Dielectric Between The Plates.

The Capacitive Sensor Can Detect Any Targets Whose Dielectric Constant Is More Than Air

Inductive proximity sensors working principle

Inductive proximity sensors detect the presence of metallic objects.

Their operating principle is based on a coil and high frequency oscillator that creates a field in the close surroundings of the sensing surface. The presence of metal in the operating area causes a change in the oscillation amplitude. This change is identified by a threshold circuit, which changes the output of the sensor. The operating distance of the sensor depends on the coil’s size as well as the target’s shape, size and material.

Construction

The proximity inductive sensor basically consists of a wound coil located in front of a permanent magnet.

The permanent magnet is encased in a rugged housing.

The change in current in the coil is output through the leads embedded in the resin.

The leads connected to the display through a connector gives signal for the presence of an object in the vicinity.

Advantages

- They are very accurate compared to other technologies.

- Have high switching rate.

- Can work in harsh environmental conditions.

Disadvantages

- It can detect only metallic target.

- Operating range may be limited.

Capacitive proximity sensors

Capacitive Sensor Are Used For Non Contact Detection Of Metallic Object And Non Metallic Object(liquid, Plastic, Wooden Material Etc.)

Capacitive Proximity Sensors Use The Variation Of Capacitance Between The Sensor And Object Being Detected.

Capacitance Methods Are Very Sensitive , Distance Down To One Micro Inch Can Be Measured.

Construction and working

The Main Components Of The Capacitive Proximity Sensor Are Plate, Oscillator, Threshold Detector And The Output Circuit.

The Plate Inside The Sensor Acts As One Plate Of The Capacitor And The Target Acts As Another Plate And The Air Acts As The Dielectric Between The Plates.

The Capacitive Sensor Can Detect Any Targets Whose Dielectric Constant Is More Than Air

Capacitive proximity sensors working principle

Capacitive sensors are used for non-contact detection of metallic objects & nonmetallic objects (liquid, plastic, wooden materials and so on). Capacitive proximity sensors use the variation of capacitance between the sensor and the object being detected. When the object is at a preset distance from the sensitive side of the sensor, an electronic circuit inside the sensor begins to oscillate. The rise or fall of such oscillation is identified by a threshold circuit that drives an amplifier for the operation of an external load.

Advantages

- It can detect both metallic and non metallic targets.

- Good stability

- High Speed

- Capacitive sensors are good in terms of power usage

- Low cost

Disadvantages

- They are affected by temperature and humidity

- Difficulties in designing

- Capacitive proximity sensors are not as accurate compare to inductive sensors.

Ultrasonic Sensor

Ultrasonic Sensor Are Some Type Used In Place Of Optical Sensors . Instead Of Using An Light Beam , A High Frequency Sound Wave Is Used.

This Sound Wave Is Above Normal Hearing Frequencies And Are Called Ultrasonic Frequencies Around 40 KHz Are Common.

The Ultrasonic Sensor Can Measure Distances In Centimeters And Inches. It Provides Good Readings In Sensing Large-sized Objects With Hard Surfaces.

Ultrasonic Sensor working

The ultrasonic sensor sends out sound and receives it back using the receiver. Together, the ultrasonic sensor's sender and receiver look like a pair of eyes, but it is not a sight sensor. Instead, those "eyes" are really more like a speaker and a microphone (a sound sensor).

Advantages

- Ultrasonic proximity sensors are not affected by atmospheric dust, snow, rain..etc

- Can work in adverse conditions

- Sensing distance is more compared to inductive or capacitive proximity sensors

Disadvantages

- Ultrasonic sensors Has More Difficulties Reading Reflections From Soft, Curved, Thin Or Small Objects.

Optical proximity sensor

The Proximity Of The Object Is Detected By The Action Of The Travelling Light Move.

These Sensors Use Light Sensitive Elements To Detect Objects And Are Made Up Of An Transmitter (Light Source) And A Receiver

The Object Within The Range Of The Sensor Can Detect The Presence.

The Light Emitted By The Transmitter Focuses On The Object Which Reflects To Be Received By The Receiver Photo Diode.

The Reflected Waves Travel Back And Received By The Solid State Photo Diode, Through The Receiver Lens.

Advantages

- They Are Useful And Can Help Many Security Problems.

Disadvantages

- The Can Easily Be Set Off And Cause Problems.

- They Are Expensive Than Inductive And Capacitive Proximity Sensor

Working

A proximity sensor often emits an electromagnetic field or a beam of electromagnetic radiation (infrared, for instance), and looks for changes in the field or return signal.The object being sensed is often referred to as the proximity sensor's target. Different proximity sensor targets demand different sensors. For example, a capacitive or photoelectric sensor might be suitable for a plastic target; an inductive proximity sensor always requires a metal target.

The maximum distance that this sensor can detect is defined "nominal range". Some sensors have adjustments of the nominal range or means to report a graduated detection distance.

Proximity sensors can have a high reliability and long functional life because of the absence of mechanical parts and lack of physical contact between sensor and the sensed object.

Applications

- Parking sensors, systems mounted on car bumpers that sense distance to nearby cars for parking

- Ground proximity warning system for aviation safety

- Vibration measurements of rotating shafts in machinery

- Top dead centre (TDC)/camshaft sensor in reciprocating engines

- Sheet break sensing in paper machine.

- Anti-aircraft warfare

- Roller coasters

- Conveyor systems

- Beverage and food can making lines

- Mobile devices

- Touch screens that come in close proximity to the face

- Attenuating radio power in close proximity to the body, in order to reduce radiation exposure

Comments

Post a Comment