Control Valves positioner working principle, types, operation, benefits and advantages

Control Valves positioner

What is a control valve positioner?

Control valve positioners translate signals from the control system to send the correct pressure to the actuator. In short, it tells the valve to move to a specific position based on input data, which results in remote, digital control of this mechanical device.

Control valve positioner types

Pneumatic control valve positioner

Pneumatic control valve positioners use a flapper/nozzle system. They require compressed air to make everything work properly and use 3-15 pounds per square inch of signal to receive data from the controller. Tells the coil to expand or contract depending on the input signal. Bellows move the flapper assembly and beam which measures valve stem feedback via the cam. In all these movements, the flapper will move closer to or further from the nozzle. Thus the relay will increase or decrease the air output to the valve actuator. When the valve stem moves, it sends feedback through the beam. Then based on the input signal to position the valve correctly, the air output will decrease or increase again.

Electro-pneumatic control valve positioner

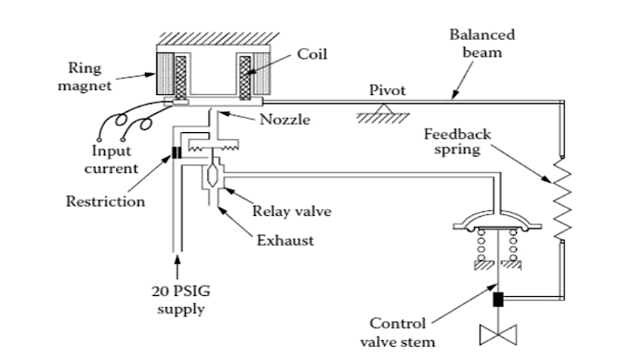

The working principle of electro-pneumatic control valve positioner is similar to pneumatic control valve positioner. But instead of a pneumatic signal, you get an analog signal, usually 4-20 milliamps.

A signal based on the electrical signal applied to the coil creates an electromotive force (EMF). This force moves the flapper and increases or decreases air in the valve actuator. You also have feedback from the valve stem and positioner to decrease or increase the output to the valve actuator if necessary.

Smart control valve positioner

Smart valve positioners bring many benefits to the end user. They provide more flexibility for setup, as well as making it easier to get diagnostics. And these diagnostics can extend the life of your valves, reducing maintenance and unplanned downtime.

You have different types of working principles which vary from vendor to vendor. So you'll find instruments with Hall-effect positioners, potentiometers, and more. Best of all, these smart positioners use loop power and give you a handful of field protocols to choose from.

Control Valve Positioner Working Principle

A valve positioner is a device used to increase or decrease the air load pressure that drives the actuator until the valve stem reaches a "position" balanced with the output signal of the process variable instrument controller. Valve positioners are used to control valves where accurate and fast control without error or hysteresis is required. Positioners are usually mounted on the side-yoke or top casing of the pneumatic actuator for linear sliding stem control valves and at/near the shaft end for rotary control valves. For the original design variant, a "mechanical feedback linkage" connected directly to the valve stem provides feedback to the controller. The process controller tells the positioner to "change" the position; The feedback linkage reports back to the positioner and confirms that a change has occurred and gives a "meaning" of the magnitude of the change in position.

Principle of Operation

The figure shows the valve positioner. A valve positioner is a force-balanced device, in which a pneumatic module is installed on a double-acting actuator to open the air. Positioning is based on the balance of two forces; One is proportional to the instrument signal and the other is proportional to the stem position. As the signal pressure acts on the diaphragm in the instrument signal capsule, the movement of the actuator stem is transmitted to the upper end of the feedback spring through the follower arm and cam, resulting in a tension change in the feedback. Spring as stem position changes.

When these opposing forces are exactly balanced, the system will be in equilibrium and the stem will be in the position called for by the instrument signal. The balance will move up or down and with the spool valve, the output pressure and flow rate will change if this opposing force is not balanced. This will move the piston until the tension on the feedback spring opposes the instrument signal pressure.

The detailed sequence of positioner operations are as follows

Control Valve Positioner Assembly

A valve positioner consists of a very high gain amplifier - this can be pneumatic, electropneumatic etc. and a feed back link that detects the actual position of the valve. The movement required to close the valve means that the input pressure drops from the controller to the bellows. The flapper moves away from the pressure after the nozzle and orifice. The pressure on the diaphragm increases and the valve closes. The feed back arm moves up by turning the cam clockwise. This causes the beam to grow by increasing the back pressure in the nozzle until equilibrium is reached again. By changing the cock, the controller's signal can be placed directly on the diaphragm

When should a positioner be fitted

- Linearizing a non-linear actuator

- When precise valve positioning is required.

- To increase the pressure that can be closed against certain actuators and valves.

- To speed up valve response.

- A positioner uses high pressure and high air flow to adjust valve position

- To increase the pressure that can be closed against certain actuators and valves.

- Acting as an amplifier

- When the valve pressure drops to the maximum operating flowrate, 5 bar for single seated valves or 10 bar for double seated valves.

- When valves are handling sludge or solids in suspension.

- Where the different pressures in the fluid may change the position of the plug

- while controlling with a wide throttling range

Benefits of valve positioners for control valves

- Faster control

- More accurate control

- More flexible configurations and functions

- Consistent valve position, even with varying pressures

- More flexible configurations and functions

- Minimal effects of friction, which causes hysteresis and dead band

Control Valve Positioner Advantages

- Fast positioning

- exact positioning

- Eliminates the effects of large gaps between valve and positioner

- Removes hysterises

- Can withstand large variations in the forces acting on the plug

- Eliminates the stickiness and friction effect of the gland

Comments

Post a Comment