Electron microprobe

Electron microprobe

An electron microprobe (EMP), also known as an electron probe microanalyzer (EPMA) or electron micro probe analyzer (EMPA), is an analytical tool used to non-destructively determine the chemical composition of small volumes of solid materials. It works similarly to a scanning electron microscope: the sample is bombarded with an electron beam, emitting x-rays at wavelengths characteristic to the elements being analyzed. This enables the abundances of elements present within small sample volumes (typically 10-30 cubic micrometers or less) to be determined, when a conventional accelerating voltage of 15-20 kV is used. The concentrations of elements from lithium to plutonium may be measured at levels as low as 100 parts per million (ppm), material dependent, although with care, levels below 10 ppm are possible. The ability to quantify lithium by electron probe microanalyzer.

The technique is commonly used for analyzing the chemical composition of metals, alloys, ceramics, and glasses. It is particularly useful for assessing the composition of individual particles or grains and chemical changes on the scale of a few micrometres to millimeters. The electron microprobe is widely used for research, quality control, and failure analysis.

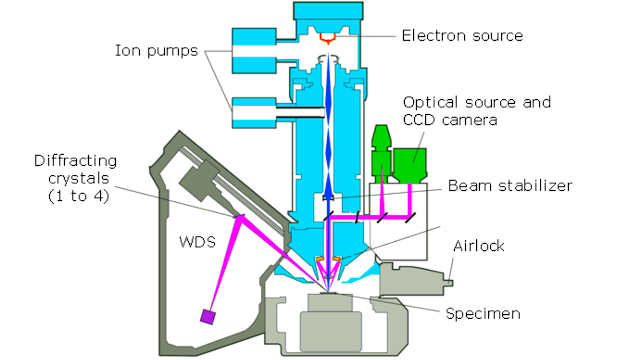

EPMA works by bombarding a micro-volume of a sample with a focused electron beam (typical energy = 5-30 keV) and collecting the X-ray photons thereby emitted by the various elemental species. Because the wavelengths of these X-rays are characteristic of the emitting species, the sample composition can be easily identified by recording WDS spectra (Wavelength Dispersive Spectroscopy). WDS spectrometers operate based on Bragg's law and use various moveable, shaped monocrystals as monochromators.

- EPMA is a fully qualitative and quantitative method of non-destructive elemental analysis of micron-sized volumes at the surface of materials, with sensitivity at the level of ppm. Routine quantification to 1% reproducibility is obtained over several days. It is the most precise and accurate micro-analysis technique available and all elements from B to U and above can be analyzed.

- EPMA is fully compatible with routine analysis sessions, with easy and direct interpretation of the results.

- EPMA instruments are equipped with a complete kit of built-in microscopy tools that allow simultaneous X-ray (WDS and EDS), SEM and BSE imaging, plus sophisticated visible light optics; they provide very flexible sample inspection with image magnification ranging from 40 to 400,000.

- Determination of thickness and elemental composition from nm to mm thick layers in stratified materials is possible.

Major applications are found in geochemistry, mineralogy, geochronology, physical metallurgy, nuclear metallurgy, materials science including glass, ceramics, superconductors, cements, microelectronics, biochemistry.

EPMA provides much better results than standard SEM/EDS systems. Because of the internal properties of WDS, the general sensitivity, analysis of light elements and risks of erroneous interpretation of qualitative spectra are all superior with EPMA. Spectral resolution and detector dead time are much better than EDS (Energy Dispersive Spectroscopy). The excitation beam regulation system and sophisticated sample stage capabilities guarantee that this technique provides outstanding stability and measurement repeatability.

Fundamental Principles Of Electron Probe Micro-analyzer (EMPA)

An electron microprobe operates under the principle that if a solid material is bombarded by an accelerated and focused electron beam, the incident electron beam has sufficient energy to liberate both matter and energy from the sample. These electron-sample interactions mainly liberate heat, but they also yield both derivative electrons and x-rays. These quantized x-rays are characteristic of the element. EPMA analysis is considered to be "non-destructive" so it is possible to re-analyze the same materials more than one time.

APPLICATIONS OF EMPA

Quantitative EMPA analysis is the most commonly used method for chemical analysis of geological materials at small scale.

EPMA is also widely used for analysis of synthetic materials such as optical wafers, thin films, microcircuits, semi-conductors, and superconducting ceramics.

Strengths And Limitations Of Electron Probe Micro-analyzer (EPMA)

Strength's

- An electron probe is the primary tool for chemical analysis of solid materials at small spatial scales .

- Spot chemical analyses can be obtained in situ , which allows the user to detect even small compositional variations within textural context or within chemically zoned materials.

Limitations

- Electron probe unable to detect the lightest elements (H, He and Li).

- Probe analysis also cannot distinguish between the different valence states of Fe.

Comments

Post a Comment