Limit switch

Limit switch

A limit switch is an electromechanical device operated by a physical force applied to it by an object.

Limit switches are used to automatically detect or sense the presence of an object or to monitor and indicate whether the movement limits of that object have been exceeded.

Types of Limit Switches

A-Shape & E-shape:

Roller lever

Levers and roller levers actuate radially, that is they rotate on an axis. Roller levers are tipped with a roller to lessen the friction and the force required to activate the lever. Levers spring-return to neutral when the force is removed. This is one of the most popular styles of switch operators.

Adjustable roller lever

Similar to a standard roller lever, but the length of the lever is adjustable anywhere from a few millimeters to up to 5 centimeters. The rollers are also available in various diameters.

B-Shape:

Rounded plunger

Plunger heads come in many varieties and sizes. Plungers are actuated by a perpendicular force applied directly to the end of the plunger.

C-Shape:

Roller plunger

When a plunger switch is needed, but the force will not be applied directly at a 90º angle, a roller plunger can be used. The roller translates some of the non perpendicular force into perpendicular force that can actuate the plunger.

D-Shape:

Rod lever

Rod levers are also actuated radially like levers; however these are thin rods that are much longer. Adjustable rods can be as long as 10 or more centimeters.

F-Shape:

Lateral rounded plunger

This plunger head varies from the standard B-shape in that the plunger is perpendicular to the switch.

G-Shape:

Lateral roller plunger

This plunger head varies from the standard C-shape in that the plunger is perpendicular to the switch.

What is limit switch?

A limit switch is an electromechanical device operated by a physical force applied to it by an object.

Limit switches are used to detect the presence or absence of an object.

These switches were originally used to define the limit of travel of an object, and as a result, they were named Limit Switch

Introduction of limit switch

Limit switches are used to automatically detect or sense the presence of an object or to monitor and indicate whether the movement limits of that object have been exceeded. The original use for limit switches, as implied by their name, was to define the limit or endpoint over which an object could travel before being stopped. It was at this point that the switch was engaged to control the limit of travel.

A standard limit switch used in industrial applications is an electromechanical device that consists of a mechanical actuator linked to a series of electrical contacts. When an object (sometimes called the target) comes in physical contact with the actuator, the actuator plunger’s movement results in the electrical contacts within the switch to either close (for a normally open circuit) or open (for a normally closed circuit) their electrical connection.Limit switches use the mechanical movement of the actuator plunger to control or change the electrical Switch's state. Hence, limit switches are contact sensors in contrast to these other types of proximity sensing devices. Most limit switches are mechanical in their operation and contain heavy-duty contacts capable of switching higher currents than those of alternative proximity sensors.

Limitations of Limit Switches

Generally restricted to equipment operating at relatively

low speeds.

Must make direct contact with target.

Moving mechanical parts will wear out.

Limit switches also have several limitations, which means they may not be suited for every application:

Because they rely on mechanical action, they generally are used in equipment that operates at relatively low speeds.

They are contact sensors, meaning they must make physical contact with the target for them to operate.

The nature of their mechanical design means that the devices are subject to mechanical wear or fatigue over time and will need eventual replacement

Advantages of limit switch

- The designs are generally simple and straightforward.

- They work well in almost any industrial setting.

- They exhibit high accuracy and repeatability.

- They are low power consumption devices.

- They can switch high-inductance loads.

- They can be used to switch multiple loads.

- They are simple to install.

- They are rugged and reliable.

- They typically have heavy-duty electrical contacts meaning they can be used to switch higher levels of current directly without the need to utilize secondary relay control.

Limit Switch Terminology

Pretravel

the distance or angle that the actuator must go through to trip the contacts

Operating Point

position of the actuator at which the

contacts snap to the operated position

Release Point

the position of the actuator at which the

contacts return to their original state

Differential

distance (degrees) between contacts trip and contacts reset

Overtravel

movement of the actuator beyond the

contacts trip point

Initial Position

position of actuator when no external force is ap-plied to the actuator

Some other important terms associated with limit switches:

Operating force (torque)

force required to move the actuating element

Minimum return force (torque)

minimum force required to return actuator to its initial position

Total Travel

the maximum allowable distance the

actuating element can travel

Repeat Accuracy

ability of a switch to repeat its characteristics precisely from one operation to the next operation

Limit Switch Uses and Operation

In most cases, a limit switch begins operating when a moving machine or a moving component of a machine makes contact with an actuator or operating lever that activates the switch.

The limit switch then regulates the electrical circuit that controls the machine and its moving parts.

These switches can be used as pilot devices for magnetic starter control circuits, allowing them to start, stop, slow down, or accelerate the functions of an electric motor.

Limit switches can be installed into machinery as control instruments for standard operations or as emergency devices to prevent machinery malfunction. Most switches are either maintained contact or momentary contact models.

Limit Switch: Construction

Working

- It is a detection switch.

- Consists of a basic switch in a metal or resin case.

- Strong outer case to protects the inside of the switch from external forces, moisture, oil, dust and dirt.

- Detecting presence/absence

- Counting

- Detecting range of movement

- Detecting positioning & travel limit

- Breaking a live circuit when unsafe conditions arise

- Detecting speed

- and hundreds of other applications

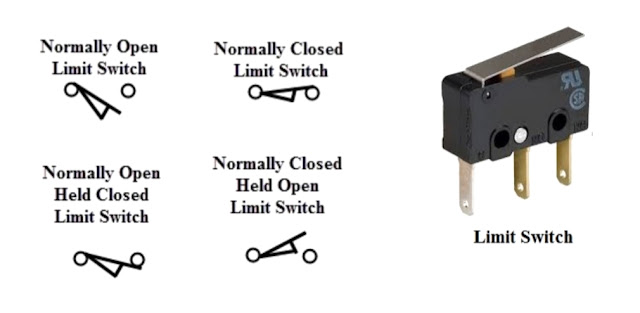

Symbol

Application of limit switch

- Position Detection for Production Lines

-Position detection for drive units (such as ones for assembly robots) and work pieces.

- Position Detection for Industrial Equipment and Devices

Comments

Post a Comment